There is no doubt about the fact that the modern supply chain is rather complex, and business leaders need all the help they can get to sustain efficient operations. After all, whichever organizations can deliver goods most speedily and with the highest degree of customer satisfaction will be the ones to outpace competitors.

To ensure productivity, many transportation and logistics companies are turning to data analytics implementation since it can empower leaders with timely insights that boost decision-making abilities. But what exactly does data analytics in supply chain operations entail? That’s what we are going to find out today.

Key Highlights

- Supply chain analytics helps businesses identify potential pitfalls early on, predict risks, and gain a deep view of their overall operations, thus opening immense growth opportunities.

- To be truly useful, a supply chain analytics solution should include key features like integration, real-time data visibility, automation, visualization, security, and digital modeling.

- Cognitive analytics not only helps uncover the main root of supply chain issues but also assists in providing human-like responses to address them effectively.

- To keep your supply chain analytics solution secure, it’s worth utilizing robust security measures like encryption, two-factor authentication, and even blockchain technologies.

The Importance of Data Analytics in Supply Chain Operations

First, let’s get on the same page and establish, what is supply chain analytics? Well, the term simply refers to the different types of data analysis that are performed by various software tools in supply chain organizations. All to help identify patterns, provide extensive visibility into operational processes, and deliver recommendations.

Data analytics is immensely important in supply chain management because of the complexities involved in procurement, inventory control, order coordination, warehousing, and shipping. With so many simultaneously moving parts, it is imperative to rely on solutions that help keep track of it all.

Core Benefits of Data Analytics in Supply Chain

Given that data analytics helps businesses gain a deep view of their operations and discover opportunities for growth, it should come as no surprise that for many companies today, this innovation has become a must-have tool. And though there are plenty of advantages analytics can deliver in supply chains, let’s take a look at the most prominent ones:

Optimize Operations

Achieving robust supply chain management is by no means an easy task. That is because there are numerous factors to consider, from procurement and logistics operations to supply chain planning and customer support. And if you want to manage all these operations wisely, you should start by leveraging data analytics.

It gives you a clear picture of what’s happening across different areas of your supply chain, helping you optimize operations.

Improve Inventory Management

Neither overstocking nor stockouts are good options for businesses. So, how to achieve wise inventory management? Typically, to get there, you need insights on demand patterns and seasonal trends. From this perspective, supply chain analytics can be a treasure trove for retail, helping not only to achieve balanced inventory but also to boost sales.

Learn more about how Data Analytics Can Help in Smarter Stock Planning

Enhance Shipment Tracking

Another critical yet challenging task in logistics is probably timely and safe transportation. Fortunately, today real-time analytics enable companies to monitor the entire shipment process, from origin to destination. Thus, providing peace of mind that the goods won’t get lost along the way.

Moreover, analytics also assist in identifying the most optimal routes, thereby reducing both delivery time and transportation costs.

Elevate Risk Management

No business is completely safe from possible risks, and neither supply chain does. To prevent possible issues damaging your business, you, ideally, should be aware of potential risks. And here again, data analytics comes in handy.

A solid supply chain planning and analytics empowered with real-time insights and predictive models give a deep view of different crucial factors from environmental conditions to supplier performance. Thus, helping to identify potential pitfalls beforehand. Only by having this insight in your hands can you develop strong strategies and partner with reliable suppliers.

Check out core technologies for Robust Supply Chain Risk Management

Identify Bottlenecks

Bottlenecks are a common part of any stage in the supply chain, whether in production, warehousing, or delivery. Fortunately, advanced analytics in supply chain management provides a clear view of each process, pinpoints the exact problem, and suggests ways of eliminating it.

Minimize Machinery Downtime

Unexpected equipment failures can not only bring production to a grinding halt but also cost a fortune. However, with predictive analytics in place, you can streamline your supply chain management by identifying potential failures early on. Therefore, minimizing costly downtime and keeping operations running smoothly.

Reduce Costs

When planning your supply chain operations, you naturally want to get things done within an optimal budget, and here, data analytics becomes your go-to. It helps reduce costs across all the activities we’ve discussed, from route optimization for efficient fuel consumption to predictive maintenance to prevent costly repairs.

BI for Business

Find out the secrets of how business intelligence boosts operations and what BI tools and practices drive data analysis.

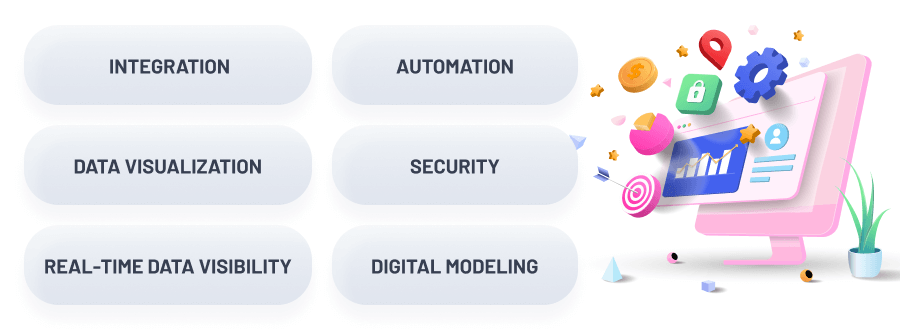

Key Features of Effective Supply Chain Analytics

So, you made up your mind to employ a supply chain analytical solution to elevate your business. And, it’s a wise move. However, do not consider that such a platform will do wonders for your business just for the sake of it. To truly get the most out of it, the solution should have these core features:

- Integration: Robust data analytics means handling structured and unstructured variables from both external and internal sources. That is to say, your platform should be able to seamlessly integrate with sources like social media, IoT, ERP, etc.

- Data visualization: To make sense, your data need to be understandable. Meaning your software should include visualization tools like charts and graphs, so you can effortlessly deal with data.

- Real-time data visibility: We’ve already emphasized the crucial role of real-time data in supply chain analytics, so it goes without saying that your platform should definitely be able to process variables instantly.

- Automation: Today, it’s hard to picture a solid platform without automation features included. The same is true for your supply chain analytics system. It should be able to collect and analyze data, as well as generate alerts and provide recommendations based on insights.

- Security: As your solution will collect plenty of sensitive information, make sure your platform meets industry-standard security protocols.

- Digital modeling: Having a digital twin of your physical supply chain processes is preferable, as it allows you to test and simulate changes before making real-world investments.

Types of Data Analytics in Supply Chain Organizations

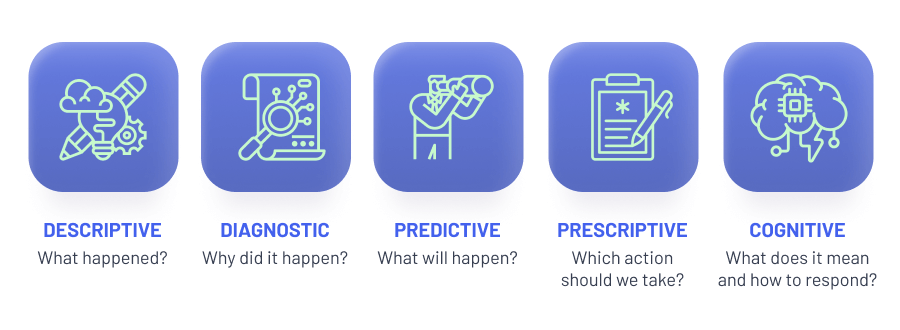

Now that we’ve got a basic understanding about the essence, pros, and main features of data analytics in supply chain, let’s get a bit more specific. Namely, it’s time to discuss the various use cases of data analytics in this sector. While the five main types of analysis that we outline below are cross-disciplinary, we will cover examples of each within the logistics sector specifically.

Descriptive

As the name suggests, descriptive supply chain analytics simply describe what has occurred. Through dashboards and reports, this form of analysis structures and summarizes key information about the supply chain.

For instance, descriptive analytics is used to answer the following questions:

- How have stock levels changed over the last month?

- How much fuel has been used by the fleet?

- How many returns have been processed in the last week?

- Under what conditions were the products transported?

Take a look at how we developed a Real-Time Cold Chain Monitoring Tool

As you can see, descriptive analytics display what has happened but offer no further information on any occurrence. Details on revenue levels, website visitor count, or the number of new leads acquired are also all based on descriptive analytics.

Diagnostic

Diagnostic analytics takes things a step further by helping establish why something has happened. In other words, it assesses the cause-and-effect relationship between variables to discover connections between data and establish patterns that may not have been noticed before.

Hence, diagnostic supply chain analytics can answer the following questions:

- What causes frequent delays in truck dispatching?

- Why are shipments being delayed or lost?

- Why did the revenue drop 3% last month?

Typically, your supply chain analytics software would first deliver insights on what’s going on in the business overall and then apply data science capabilities to identify why it’s happening.

Predictive

Now, we’ve reached some of the most exciting supply chain analytics tools. As the name implies, predictive analysis is all about forecasting what is likely to occur in the future.

Frequently, it incorporates artificial intelligence and machine learning algorithms that can go through myriads of digital information at an extremely high speed and deliver more accurate predictions.

Discover the Role of AI in Transportation

Predictive analytics doesn’t only look at historical data but often blends it with real-time information to provide the most reliable forecast about the future.

For example, many organizations are combining predictive analysis with IIoT technology by gathering data from connected devices installed in trucks or warehouses to forecast malfunctions and schedule maintenance before too much damage occurs.

Learn about the Benefits of IoT in Transportation

So, to summarize, predictive analytics can aid supply chain operators with:

- Scheduling timely asset maintenance

- Anticipating shifts in consumer preferences

- Forecasting demand

- Predicting how regulatory changes might impact the business

Prescriptive

This one probably is the most in-demand form of analysis that supply chain tools employ because it is the most complex and beneficial one. Here, the software will go as far as suggesting the next best course of action for you. Thus, ensuring that you can eliminate a problem in due time or capitalize on an emerging trend.

The reason it is the most complicated form of data analytics is because it requires that you implement all of the previous ones we’ve discussed as well, and have good data management practices in place across your organization. As you can imagine, this level of thoroughness can require a lot of work. Especially, from organizations that have yet to move on from legacy systems.

Read up on Enterprise Data Management Strategy Creation

However, this doesn’t mean that prescriptive analytics is unseen in supply chain operations. In fact, it is increasingly gaining popularity as businesses make real commitments to innovation.

So, if you choose to implement this technology, it’ll help you determine:

- Which is the best route for drivers to take amidst changing traffic conditions?

- How to optimize fuel usage?

- Is it a good idea to purchase a new warehouse?

- How do we ensure we always have enough stock with minimal additional costs?

Cognitive

Lastly, let’s talk about cognitive analytics. It looks a bit like predictive and perspective types, but the main difference is the form of variables it produces. Typically, this approach handles unstructured inputs such as text, images, or voice data. Plus, cognitive analytics utilizes advanced technologies like AI, ML, and NLP to simulate human reasoning.

As such, it helps not only understand the reason behind the main issues but also how to respond to them in a more human-like manner.

Let’s say you’ve recently received many complaints from customers about a specific shipment. So, you employ cognitive analytics to process their emails and understand their sentiment. As a result, you discovered that most customers were unhappy with the packaging of the delivered items. They wish it to be packed more securely and temperature-protected.

Cognitive analytics helps you understand the issue clearly and may suggest changing the packaging to meet customer expectations.

So, to wrap up, this analytical approach can:

- Extract meaningful insights from unstructured data

- Understand context and nuances beyond raw data

- Make decisions like a human would

Challenges in Supply Chain Data Analytics

You now know how supply chain analytics tools can help your business and the different use cases of these solutions. However, prior to jumping into development, it’s important to be aware of some of the difficulties you may face.

You see, some of the analytics you may want to run require a sophisticated software infrastructure. Plus, when you work with more and more digital information, your responsibility for ensuring its safety grows. So, let’s take a closer look at the challenges that supply chain data analytics may come with.

Data Volume

The amount of data generated by businesses is growing at an exponential rate. Every day, there is more and more digital information generated, and if you want to capitalize on it, you’ve got to first manage and store it all effectively.

In this regard, many opt for data lakes or data warehouses implementation to make sure everything is stored securely and can be easily accessed for work. Of course, developing these systems is likely to take some time and investment, but it is an absolute must if you’re serious about leveraging data analytics.

Take a look at the Differences Between Data Lakes and Warehouses

Data Silos

Another major difficulty you may encounter when seeking to implement supply chain analytics software is the presence of various data silos. You see, in logistics and transportation, information is often distributed among many disparate systems — enterprise applications, CRM platforms, third-party tools, and the like.

With so many sources, it can be difficult for algorithms to identify patterns that emerge across data silos. Thus, it’s imperative to first integrate data from all relevant apps so that you can truly benefit from analytical solutions.

Discover how we performed VoIP System Integration with a CRM

Data Quality

As you can imagine, making decisions based on outdated or incomplete information can result in major mistakes, missed opportunities, and even higher costs. So, it’s a good idea for your IT team to perform any data cleansing, aggregation, enrichment, and other quality assurance activities before you begin building data analytics platforms.

After all, if you can get rid of duplicates, inconsistencies, and other data errors ahead of time, there will be fewer issues to deal with down the line.

Data Security

Lastly, whenever you work with extensive amounts of data, ensuring security becomes increasingly important. Across the entire data ecosystem, information must be safeguarded, no matter if it is in transit or simply being stored.

So, consider adding encryption mechanisms, two-factor authentication, and other practices that help prevent data leaks, theft, and destruction. Or, take it a step further and implement blockchain technology to leverage decentralization and cryptography for an added level of security.

Find out how Blockchain Protected a Clinic From Security Breaches

Incorporate Good Data Practices

As you can see, there is a lot to keep in mind when it comes to data analytics in supply chain operations. You’ve got to know the objectives you’d like to achieve with this technology and how to deal with the potential challenge. However, you don’t have to go at it alone.

At Velvetech, we are pleased to offer extensive data analytics services to clients from all kinds of industries. Yet, we often work with transportation and logistics providers and are thus well equipped to help with your unique business scenarios.

So, don’t hesitate to reach out to our team via the form below and discuss your project with our specialists. We are always excited to take on new initiatives.