In the modern day, data lies at the core of any well-functioning business as it delivers actionable insights and facilitates timely decision-making. Everyday more and more digital information is created, and the industrial sector is particularly overflowing with data that is collected from widespread Internet of Things (IoT) devices.

Naturally, managing the computing powers that handle all this is getting increasingly challenging. Thus, latency grows, network disruptions halt operations, and bandwidth limitations hinder efficiency. To cope, organizations are starting to look into IIoT edge computing.

“Edge computing tackles a growing demand to address lower latency, process the growing amount of data on the edge and support resilience to network disconnection.”

— Gartner

If you aren’t sure what industrial edge computing is all about — don’t worry, that’s precisely what we are setting out to discuss today. We’ll start by describing what this technology actually is, the benefits it can deliver, and finish up with the top edge computing use cases within the industrial IoT sphere.

Let’s dive in.

Understanding IIoT Edge Computing

Before getting into the nitty-gritty details of how edge computing can be used in the industrial sector, let’s first get on the same page about what the term means.

In short, with edge computing, parts of data storage and processing are moved closer to the sources of the data themselves. So, instead of having all the information transferred to a central data center or the cloud, a portion of computing occurs “at the edge”, near to where the data was generated.

As a result, relevant analysis occurs locally which enables swift decision-making. At the same time, the rest of the data can be transferred further for more complex computations powered by artificial intelligence or machine learning algorithms.

Discover the Role of AI in Business

Benefits of Industrial Edge Computing

Now that the definition is out of the way, let’s move on to what truly interests you — the advantages to acquire with this technology. The truth is, edge computing can bring ample benefits for those who’ve implemented industrial IoT solutions. However, we’re going to focus on the four most prominent ones.

Higher Performance

As opposed to centralized computing, edge facilitates higher performance thanks to local data processing. This way, long-distance transmission occurs less frequently and only for digital information that requires more in-depth analytics.

You see, when the system is dealing with time-sensitive operations, it is crucial for data to be analyzed swiftly so that automation processes can kick in and fix any potential issues. With edge computing, this becomes possible as latency is reduced, performance is boosted, and response time is drastically improved.

Better Security

Another major advantage of industrial edge computing is better security. As you may know, cloud computing is sometimes associated with heightened risks of data tampering, cyber attacks, and information leaks. This is because digital information has to travel over the network to the cloud and get stored in a centralized manner.

Of course, there are plenty of ways that cloud providers ensure security. Nonetheless, levels of safety tend to be higher with edge computing as the majority of data is processed locally and risks are split between smart sensors and the cloud.

With edge, there are less points of failure that can be exploited as IIoT devices can be set up to operate independently and shutdown if compromised. Thus, restricting access to the broader IT infrastructure.

Improved Scalability

The requirements of any business tend to evolve as time goes on. Some need to scale up rapidly while others realize that they would do well by reducing the use of certain resources. However, not all IT tools facilitate scalability, but edge computing does.

Thanks to the distributed nature of edge devices and the connection with the cloud, companies can easily scale up or down as needed. If you require more devices to be installed or cloud storage to be expanded — no problem. It can be done without shutting down operations and significantly disrupting existing workflows.

Lower Costs

Finally, edge computing can help you save money in the long-run. After all, instead of sending myriads of digital information to the cloud or a server, time-sensitive analytics occur at the edge and only the most important data is transferred.

As you can imagine, this can really reflect positively on your bottom line as computation and data storage needs are reduced.

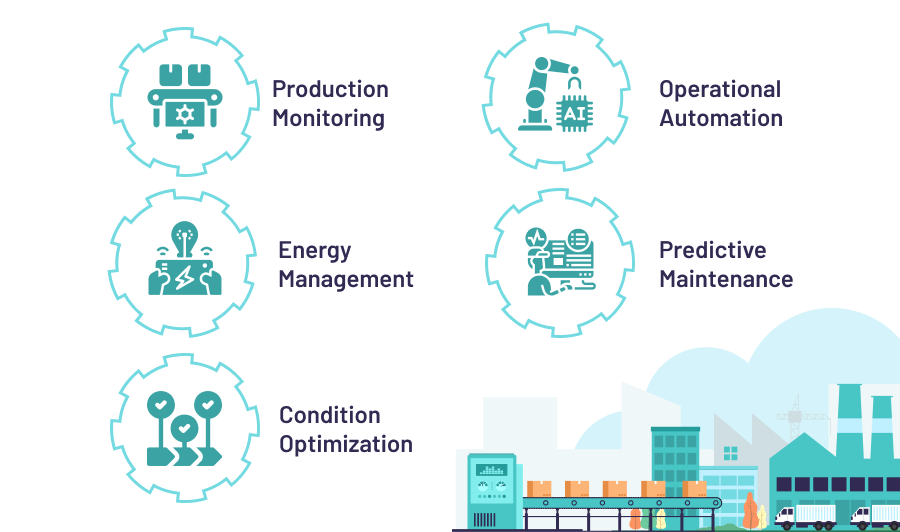

5 Top IIoT Edge Computing Use Cases

Although industrial edge computing is a relatively new concept, it is steadily gaining popularity. Already, there are numerous examples of how the technology is used within the industry and they will only continue to grow in the coming years.

Below, we’ll take a look at the most popular edge computing use cases to date so that you can determine which might benefit your company most. Let’s get into it.

1. Real-Time Production Monitoring

One of the primary IIoT edge computing use cases is definitely for real-time monitoring. As you know, in industries like manufacturing, any issues during production can have enormous negative impact. Whether some minor mishap occurs on the production line or a machine malfunctions — the quicker you can react and fix it, the better.

Find out more about the Power of IoT in Manufacturing

As we’ve already mentioned, with edge computing, timely decision-making is easy to accomplish. Since data is captured by connected devices and swiftly analyzed at the edge, monitoring asset health and production efficiency in real-time is less of a challenge.

Thanks to edge computing, your company won’t have to deal with transmission delays or an overwhelmed centralized system. Instead, whenever an issue occurs, the system immediately alerts employees, or, if relevant, initiates automated workflows to fix it. Thus, helping avoid major disruptions and delays.

Check out how Velvetech built an IIoT System for Monitoring Anchor Installation

2. Operational Automation

In relation to the previous point, leveraging edge computing in IIoT tools helps automate various operational procedures. Since data processing occurs closer to the sensors and latency is reduced, automated workflows can be set up so that problems are fixed without human involvement.

For example, if your manufacturing facility employs computer vision-powered cameras for monitoring product defects on the assembly line, it will benefit from the swiftness of analysis at the edge. This way, faulty items will be quickly spotted and automatically set aside without going further through the production process.

“By gathering, processing, analyzing and interpreting the data at the device edge, businesses can gain faster insights into the conditions on hand, thereby allowing automated actions to be rolled out to ensure the business’s overall safety and smooth operations.”

— IBM

3. Predictive Maintenance

Machine failure or equipment malfunction can quickly rack up unforeseen expenses for a company. Not to mention, it forces you to slow down operations as repairs are carried out, putting a dent in your usual revenue levels.

As you may guess, IIoT solutions and edge computing can minimize such occurrences. As smart devices continuously monitor your equipment and gather information, data analytics algorithms look for patterns that may indicate future machine failure. If the system predicts a malfunction, it will alert your staff so that relevant maintenance procedures can be scheduled before major shutdown occurs.

Of course, this capability is already present in IoT applications that work without edge computing. However, it is precisely with the help of the latter that swift maintenance action can be taken as no transmission delays hinder the analytical work.

4. Energy Management

Sustainability is a hot topic among industrial leaders, and with good reason. Eco-friendly practices aren’t just good for the planet but can actually boost your bottom line as well. Fortunately, edge computing has a role to play in this department too.

Learn more about Industrial IoT and Sustainability

The industrial sector can benefit immensely from energy usage monitoring and control. You see, even a simple power down during peak times can result in significant cost savings. So, relying on edge applications that can automatically adjust and optimize consumption based on fluctuating prices can be game-changing for organizations. If your interest is peaked — definitely discuss this use case with your IT team or software development partner.

5. Transport Condition Optimization

Lastly, edge devices have the capacity to revolutionize supply chain and logistics operations by improving condition monitoring. If your company is involved in the transportation of perishable or temperature-sensitive products, you know why this is so important. After all, even a seemingly minor change in conditions during transportation can lead to items being unusable.

With condition monitoring, time is of the essence and that’s precisely why edge computing can prove invaluable. With it, the connected devices installed in trucks or containers will analyze temperature and other details swiftly and alert relevant staff or adjust conditions automatically. Thus, ensuring that no mishaps, loss of product, and subsequent financial implications occur.

Read over one of our successful Cold Chain Monitoring Projects

Leverage Edge Computing For Your Business

Whenever a new technology arrives to impact the world of business, it is met with skepticism and hesitancy due to the lack of understanding about its potential. Edge computing is no exception. However, recently, it’s become increasingly evident that the IIoT sphere is embracing this innovation because of the ample benefits it’s already proven to deliver.

From real-time production monitoring to energy management and predictive maintenance — IIoT edge computing use cases are peaking the interest of business leaders across sectors. Hence, if you don’t want to fall behind and are eager to leverage smart devices for organizational growth, feel free to reach out to our team.

Velvetech’s specialists have years of expertise in IIoT solutions development and understand the intricacies of making hardware and software work together effectively. We’d be happy to collaborate on your next project; simply fill out the form below, and we’ll get back to you shortly.