If you are reluctant to accept changes and implement high-tech solutions into your workflows — you are doomed to be a step behind those who are open-minded to innovations. This concept of the importance of digital transformation is already well-learned by businesses from various spheres including manufacturing.

At the International Manufacturing Technology Show (IMTS), industry leaders come together to share expertise, present new solutions, identify emerging trends, and tackle the challenges on the path to comprehensive digital transformation.

Yuri Yushkov, Velvetech’s founder and CEO, visited the gathering held on Sept 9-14 and shared his insights on where the industry is steering the course and how our accumulated expertise can help manufacturers adapt to new realities through technological solutions.

Insights We’ve Taken from the Exhibition

AI Is Anywhere and Everywhere

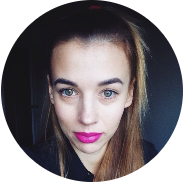

The abundance of value propositions propelling AI-powered solutions catches the eye right when you cross the threshold of the exhibition. Although the trend isn’t new, in recent years, manufacturers have started to leverage its capabilities across a broader range of internal processes. This spans from product quality control to AI-enabled robots capable of performing complex production tasks with the ultimate level of accuracy.

Another niche AI is being used for is effective data management and analysis. Obviously, manufacturers manipulate huge datasets from product lines, sensors, management systems, etc. A normal human is physically not able to analyze big data volumes in a short time and build comprehensive real-time reports.

Unlike a human, AI can do it quickly and much more precisely. Also, ML models can easily identify patterns and offer improvements in manufacturing operations. Worth mentioning that major cloud providers like Google or Amazon offer specific services intended for ML model design, which can also work in conjunction with Computer Vision and help with data processing.

How Can We Contribute?

Velvetech possesses extensive experience in building effective AI-enabled solutions. Combining them with IoT solutions embedded into your pieces of equipment, we can help you establish efficient data collection and analysis processes to perform better control over manufacturing operations and machinery conditions.

Sustainable Trend for Low-Code/No-Code Solutions

This year we can observe that the approach to the implementation of production processes is gradually shifting to the introduction of low-code and no-code solutions. The reason is quite simple, such systems are maximally flexible and help companies to quickly adopt CRM or ERP systems, roughly speaking, speed up their digital transformation processes.

At the event, manufacturers highlighted the advantages of low-code/no-code systems mainly for managers monitoring production processes, but lacking software development skills. For example, employees who are dealing directly with machines or assembly stands can easily control operations through low-code/no-code processes. In other words, using such systems, they are empowered to conduct manufacturing operations fine-tuning without any necessity to write code.

Explore more about Low-Code Development

How Can We Contribute?

Here we also have something to offer. For one of our clients, we developed a low-code warehouse management system designed specifically for warehouse staff to streamline operations and optimize order fulfillment.

The software supports every warehousing process, from product receipt to packing and dispatch preparation, covering the full order fulfillment cycle. While the system we developed focuses solely on workflow processes, the principles of production process management are very similar. This means our team can easily create and customize similar low-code/no-code systems for companies in the manufacturing sector.

Maximum Automation of Inner Processes

IMTS attendees emphasize that manufacturing companies strive to move away from tedious manual tasks and replace them with automation, without sacrificing quality. That’s why they introduce ERP/CRM systems to effectively manage inner workflows and enhance interaction with customers. Such software is used as a universal all-in-one solution intended for sales and marketing automation, resource planning, order management, and more.

Manufacturers utilize Workday, Salesforce, or any other specific software. However, they need these systems to cover their particular workflows and production processes, that’s why they can’t do without appropriate customization.

How Can We Contribute?

Partnering with Microsoft, Salesforce, and Creatio, we bring extensive experience in customizing CRM and ERP platforms from these leading providers. Whether it’s Dynamics 365 or Salesforce, we can tailor these solutions to meet your specific business requirements, ensuring they effectively address all critical aspects of your manufacturing processes.

Additionally, our team includes certified Creatio CRM developers who can fine-tune your workflow-related processes to streamline your interaction with suppliers and customers within this low-code platform.

IoT and Industrial Automation

Manufacturing processes and product quality monitoring, automation, predictive maintenance — in current realities this scope of tasks seems infeasible without IoT and various embedded devices. However, the development and introduction of a bunch of sensors is a long and not-an-easy story.

That’s why manufacturers are looking for ways to circumvent the issue and integrate IoT solutions as quickly and seamlessly as possible. And such a chance has come up recently.

At this exhibition, Amazon presented its proprietary framework for device and sensor development along with the concept of how to work with this code within the Amazon environment. Why is this definitely worth your attention? Because such frameworks feature a ready-made toolset, including libraries and templates, which significantly simplifies and accelerates the devices’ development and further implementation.

How Can We Contribute?

Our team offers a full spectrum of IoT development services, starting from consulting and ending up with embedded software development. Being included in Amazon’s partner program, we can use their framework and follow the best practices to design devices that correspond to your requirements.

We have our own custom solutions that we can offer out-of-the-box and do a quick cycle of prototyping and PoC so you can gain a working, high-quality solution in the shortest time possible.

About IMTS

The International Manufacturing Technology Show, first held in Cleveland in 1927, has grown into the largest and most prestigious event of its kind in North America. Nowadays, IMTS brings together industry leaders, technology innovators, manufacturers, and sellers from across the globe to explore and exhibit cutting-edge advancements in manufacturing technology.

Today, IMTS is held every two years in Chicago, drawing thousands of attendees and exhibitors. The event showcases a wide array of technological innovations in fields such as automation, robotics, additive manufacturing, machining, digitalization, and more. With its comprehensive focus on the future of manufacturing, IMTS serves as a critical platform for businesses to discover the latest trends, establish partnerships, and gain insights into the rapidly evolving landscape of industrial technology.