- Project: Implementation of IIoT solution to monitor helical pile installation data

- Duration: 16 months

- Technologies: Swift, Kotlin, .NET

- Target audience: Company’s customers

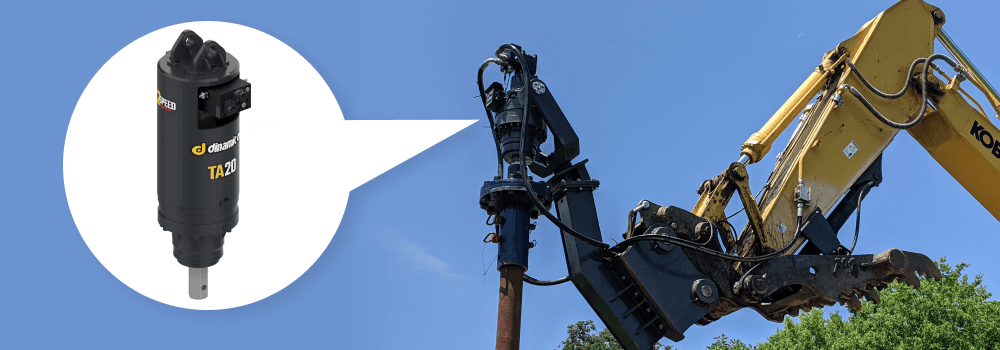

Dinamic Oil North America is a subsidiary of Dinamic Oil S.p.A., supplying customers with gearbox, hoist, and anchor drive products. Their services support various industries with drilling, mining, industrial, and energy solutions powered by the latest technologies.

THE CASE

The Client delivers to the market anchor drives that help their customers perform construction operations. Comprehending the technology potential, the company wanted to amplify its gear with a software solution to process core data and monitor helical pile installation. Essentially, it would help them gain a competitive advantage.

Process

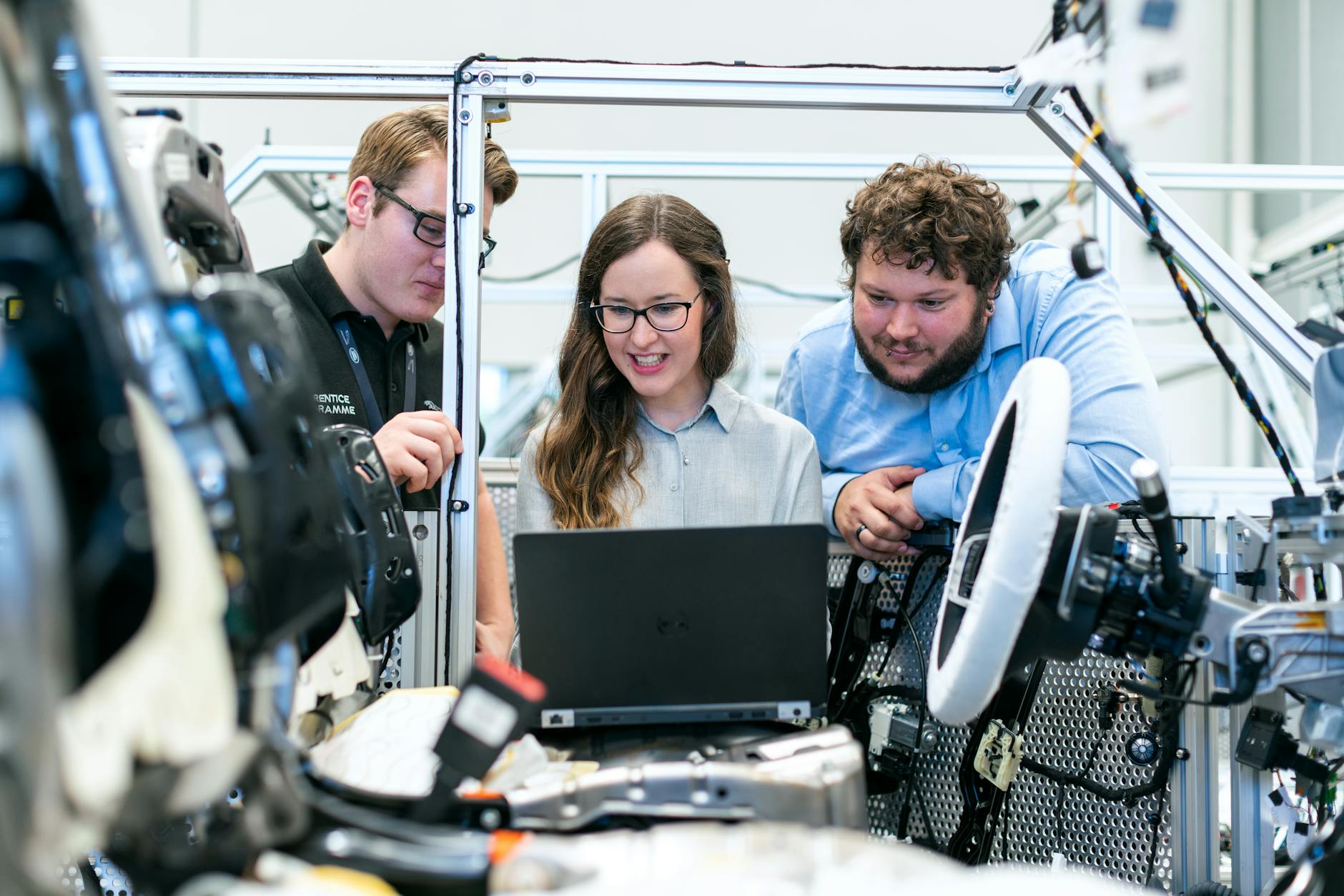

When Dinamic Oil approached Velvetech, they had already validated their project idea. Having mobile app wireframes at hand and a vision of how it should function, the Client needed help to design an entire IIoT system that would provide unique benefits to their customers.

Experienced in crafting Internet of Things solutions for various business domains, Velvetech focused its efforts on addressing the Client’s needs by delivering a smart industrial IoT ecosystem for their niche.

In order to achieve that, our team of software engineers and developers came up with an agile implementation plan that included several key phases:

- Developing hardware

- Designing a mobile app

- Building a desktop solution

Torque, Speed, and Pressure Sensor Development

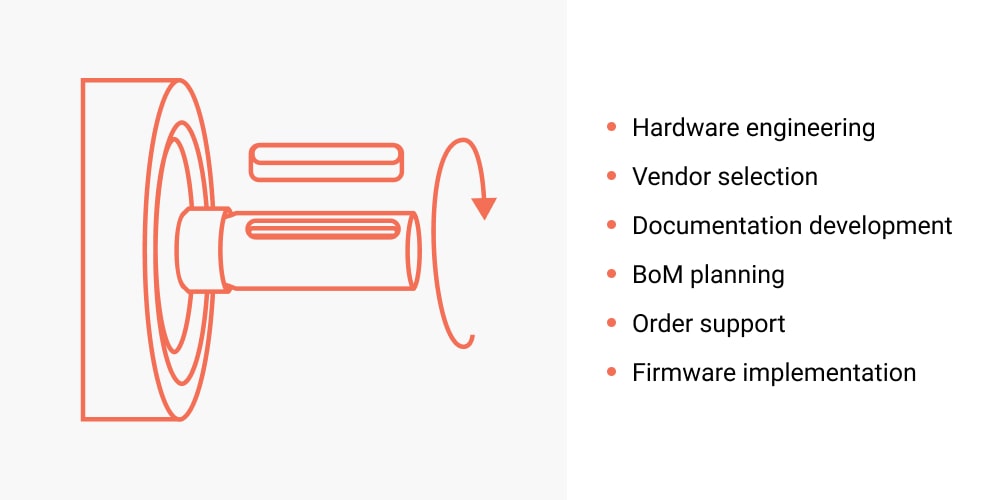

To ensure data collection and its transfer for further processing, Velvetech first assisted the Client with hardware development. We helped the company choose a reliable vendor to produce torque, speed, and pressure sensors based on the requirements that our team prepared. It was important to provide all necessary documentation with components description, bill of materials, and order support.

At the same time, Velvetech worked on the firmware implementation for sensors to transmit the data. It was decided to use Wi-Fi technology to pass such measures as the anchor drive’s pressure, temperature, torque, installation depth and angle.

Apparently, those metrics should be displayed somewhere in order to generate value for users. So the next task our team tackled was mobile app development and its integration with sensors to collect and process the data.

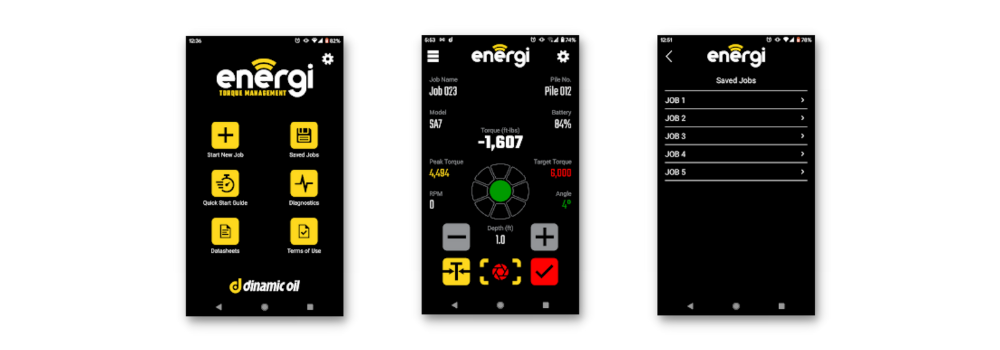

Mobile Apps Implementation

Having successfully completed numerous projects in mobile app development, we could support Dinamic Oil with our expertise to build an efficient mobile solution. The company wanted to build two separate apps. The first one was to display and monitor torque and speed data, and another one — was to do the same with pressure data.

Since native applications generally provide better performance and user experience, it was agreed to design independent apps for iOS and Android platforms. The solutions were built with a native technology stack including Swift and Kotlin programming languages that ensured rich functionality, fast operations, and high security.

Learn more about a Native Mobile Tech Stack

Both apps integrated with sensors collect and display a wide range of dynamic anchor drive measures. It can be done automatically with a preset time interval or upon the user’s request. Another essential functionality is generating PDF reports on piles installation that a user can view in the app, save to the device, add to Google Drive, or send via email.

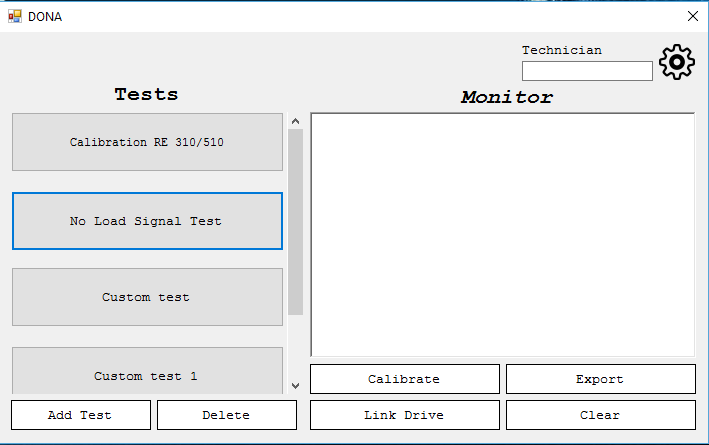

Windows Desktop App

Before selling the gear to customers, Dinamic Oil runs a range of various tests. To facilitate the process and avoid errors caused by manual data entry, the company needed a desktop application.

With a robust experience in .NET development, our team built a Windows desktop app that has a simple and intuitive design as was required by the Client. The app allows the company’s staff to manage the input of the information into a database and eliminate any possible mistakes. This way, test implementation runs more smoothly and efficiently.

The solution also enables employees to generate reports and certificates of quality to provide the company’s customers with all essential documentation during the sales process.

Outcome

The construction industry is considered to be quite conventional, and thus the adoption of new tech – including construction software solutions – can entail a great outcome for the companies that embrace them.

As a result of our partnership, Dinamic Oil gained a solid competitive advantage since similar smart Internet of Things systems can be rarely found in this niche. The IIoT solution developed by Velvetech became a core differentiator for the Client and helped win a valuable deal.

Principally, the system empowered the company’s gear products and provided the ground to improve sales opportunities. Torque, speed, and pressure sensors complemented by mobile and desktop apps offered more transparency and control over the helical pile installation and ensured the monitoring of essential data.

What’s Next

Although the project implementation of all sensors has terminated successfully, the collaboration between Velvetech and Dinamic Oil continues further. Product release set the stage for the company to keep exploring new opportunities and forging its competitive advantage.

The industrial IoT system was delivered for the anchor drives produced by Dinamic Oil. Now the company plans on making the solution available for retrofitting existing anchor drives in the customer’s fleet. It means that our teams will work on the next phase of the project, developing another version of the software.

Our specialist will contact you to schedule a personalized consultation within one business day.

Velvetech offers complimentary consultations; after which, we will provide you with a proof of concept in just 3 days, an accurate outlook of the cost and timeline of your project and a competitive estimation, and an assembled team – ready to start your project within 7 days.

Proof of Concept in

Start Project within